R.SPACE

-

Founded in 2019

2019

-

Plant area

7500

㎡ -

Core technologies

30

+

Founded in August 2019, it was co-sponsored by core technical experts from aerospace systems and Internet entrepreneurs. The founding team is mainly in the field of research and development and manufacturing of key systems and core components of launch vehicles, especially in liquid rocket power systems. In terms of propellant storage tank system, pressurized conveying system and its integration with engine system, it is composed of many industry experts with core technology and rich process experience. The industry professional investor Yuanhang Capital has provided angel round investment support to the company.

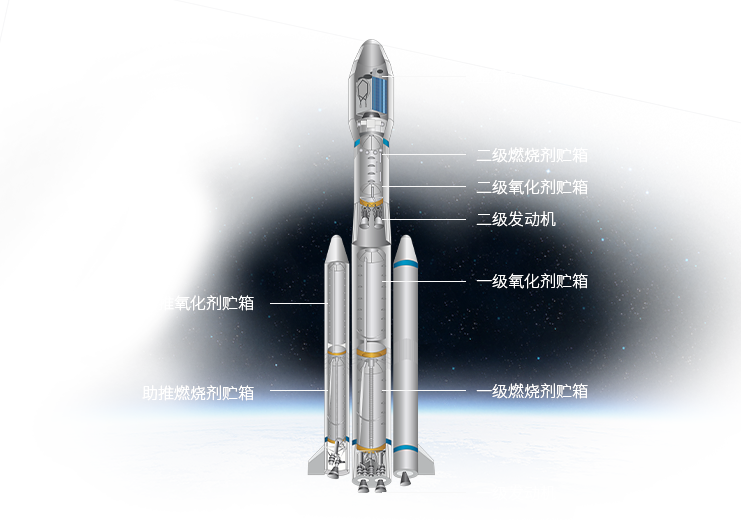

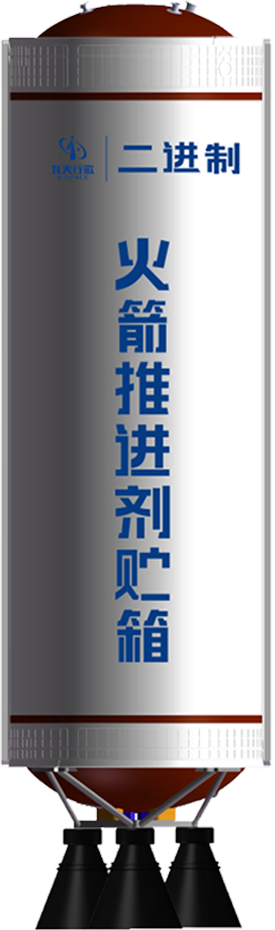

Storage box products

The breakthrough of the melon flap forming technology for the 10-meter storage tank has laid a solid foundation for the development of the principle prototype of the 10-meter storage tank of my country's heavy-duty launch vehicle (Long March 9), and has also made outstanding contributions to the lightening of the rocket structure.

Aerospace accessories

Level 2250

Engines that can be installed: 1 to 2

Thrust range: 10~100t

Working pressure: force 0.4MPa

Length: optional

Adiabatic: Adiabatic / Non-Adiabatic

Common base: optional

Pressurized delivery system: optional

Level 3350

Engines that can be installed: 1 to 5

Thrust range: 30~350t

Working pressure: force 0.4MPa

Length: optional

Adiabatic: Adiabatic / Non-Adiabatic

Common base: optional

Pressurized delivery system: optional

Level 3800

Engines that can be installed: 1 to 9

Thrust range: 100~700t

Working pressure: force 0.4MPa

Length: optional

Adiabatic: Adiabatic / Non-Adiabatic

Common base: optional

Pressurized delivery system: optional

Level 4200

Engines that can be installed: 1 to 9

Thrust range: 100~850t

Working pressure: force 0.4MPa

Length: optional

Adiabatic: Adiabatic / Non-Adiabatic

Common base: optional

Pressurized delivery system: optional

Level 5000

Engines that can be installed: 1 to 9

Thrust range: 100~1200t

Working pressure: force 0.4MPa

Length: optional

Adiabatic: Adiabatic / Non-Adiabatic

Common base: optional

Pressurized delivery system: optional

Parameters

▶ Separate single bottom and low temperature common bottom

▶ Diameter: 2250~5000mm

▶ Length: 3000~30000mm Working pressure: 0.4MPa

▶ Volume: 5~480m³

▶ Applicable temperature zone: -253℃~150℃, local ≥ 1300℃

▶ Structural efficiency: ≥0.95

▶ Material: aluminum alloy base + thermal insulation layer (optional)

▶ Conveying pipe form: tunnel pipe

▶ Built-in anti-slosh, vortex elimination, energy dissipation, sensors, filters and outflow devices, etc. and propellant stability management system

▶ Pressurized delivery system (optional)

Steel tanks can be modified according to requirements, side long row hoods and sandwich core solutions

NEWS CENTER

Join us to explore

We are committed to innovation and constantly challenge the limits of technology. We firmly believe that everyone on earth will enjoy the convenience brought by space resources.

Tel:010-81287800

E-mail:r-space@rspace2019.com

Add:202-1, Block 1, Hongkun Financial Valley, Xihongmen Town, Daxing District, Beijing

Official WeChat

Mobile